SHORT NEWS

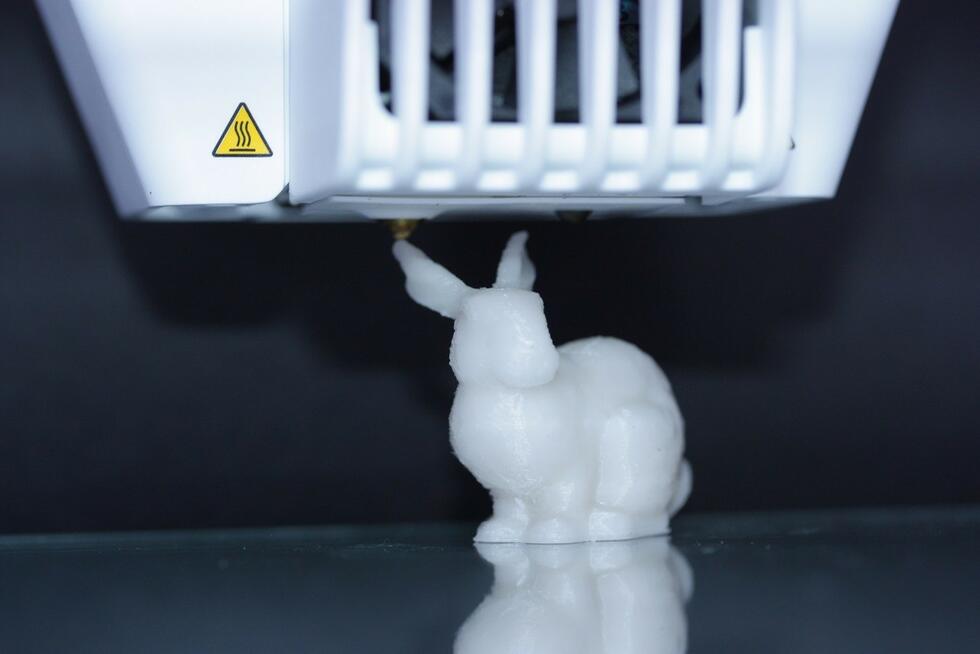

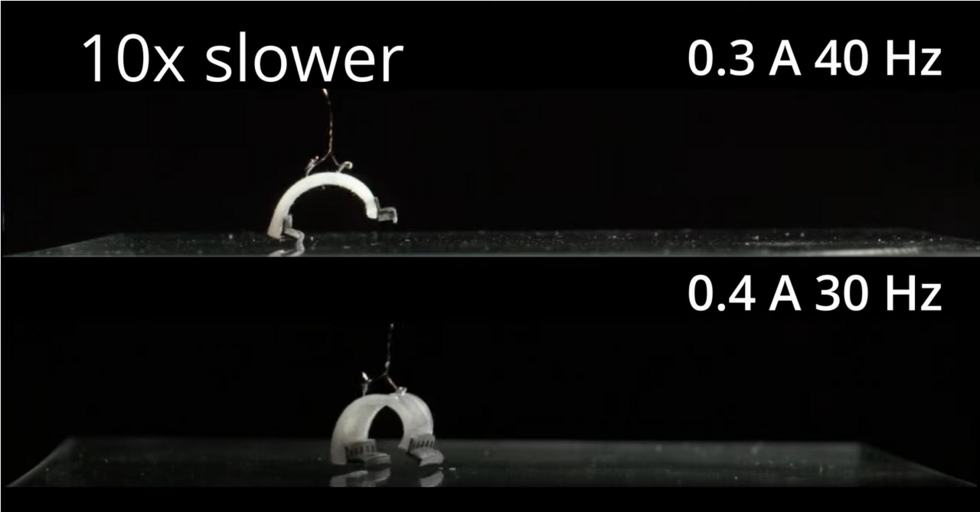

3D printer moulds robots without laborious assembly

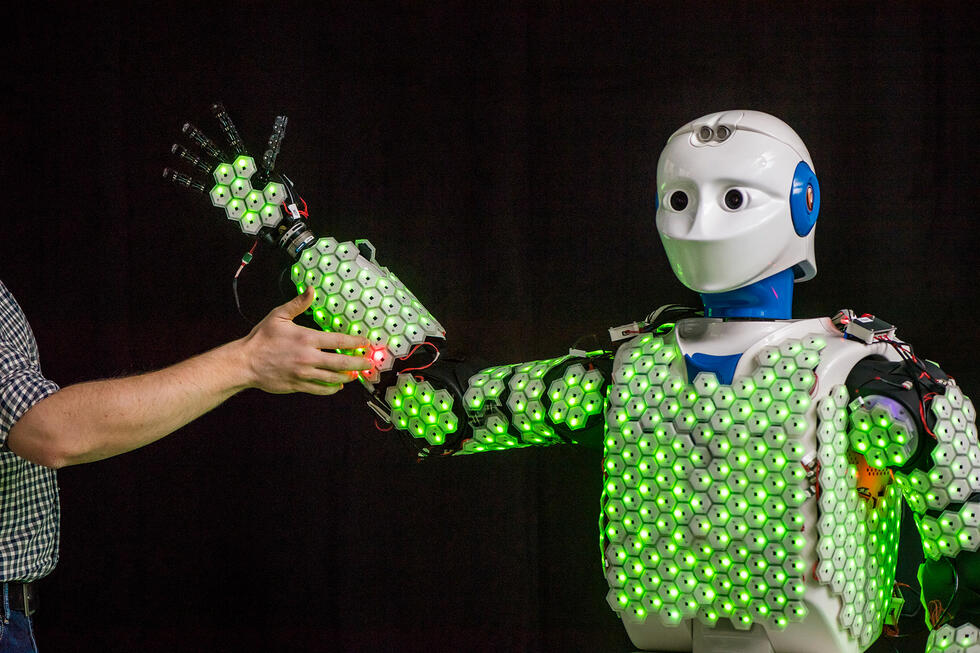

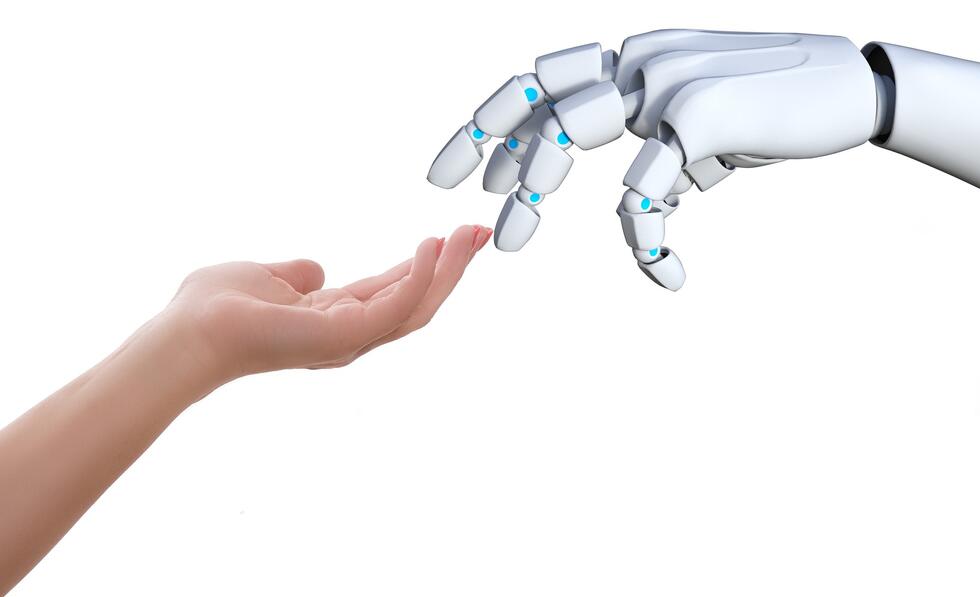

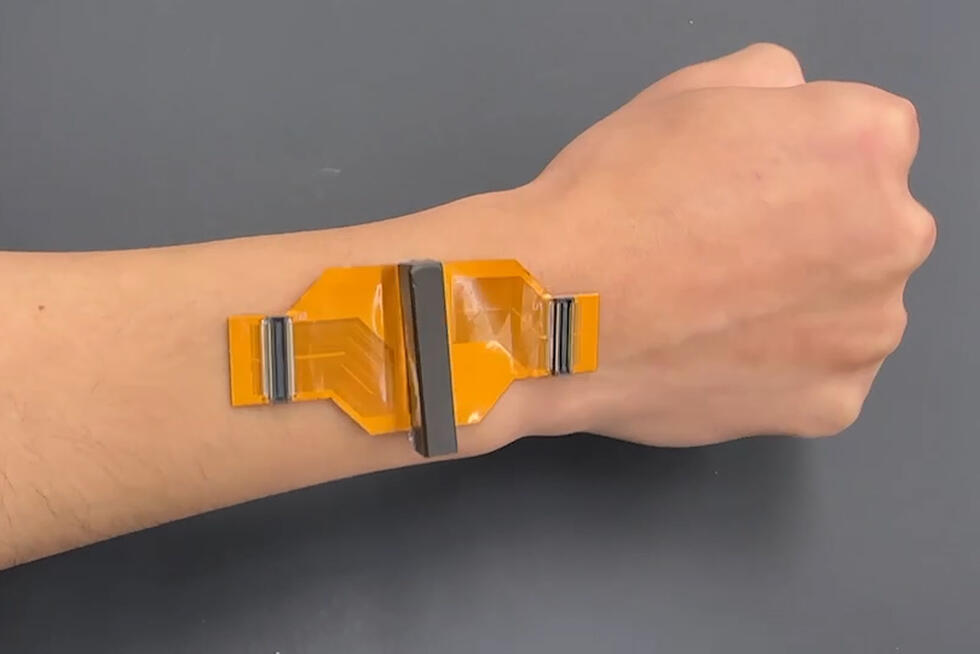

Robotic hands with bones, ligaments and tendons straight from the printer: this is made possible by a new 3D printing technology developed by researchers in Zurich.

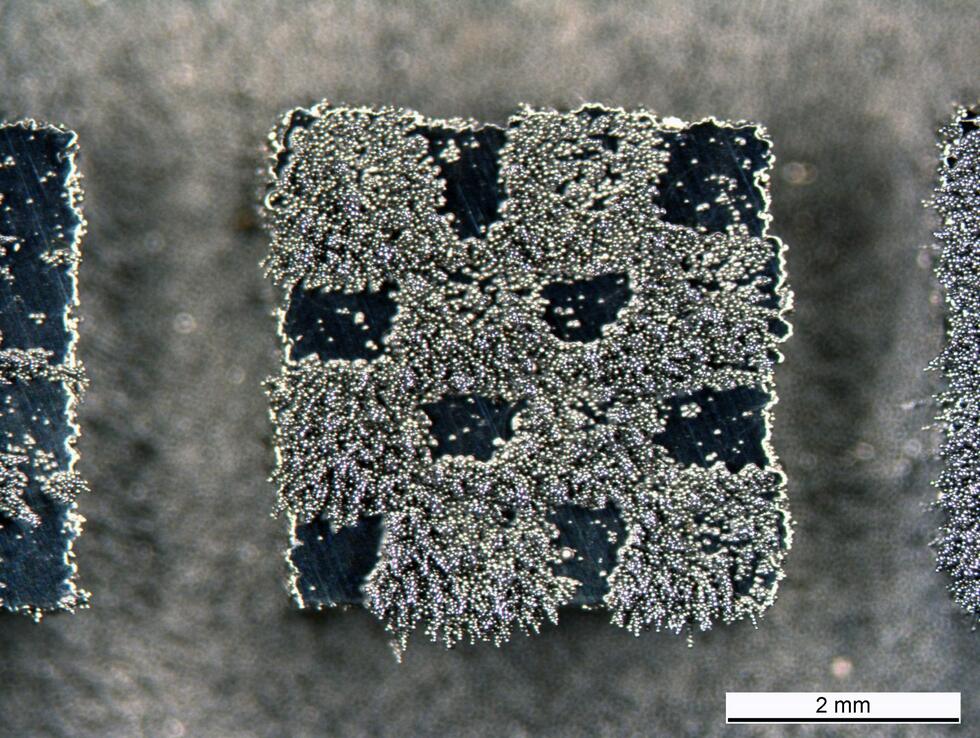

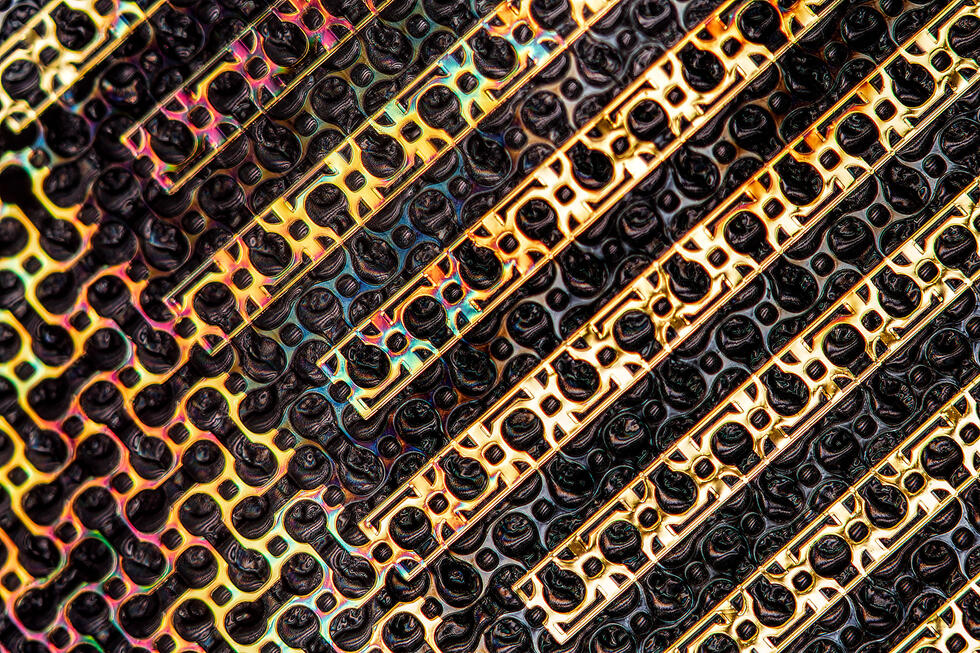

With this new technology, systems made of different materials can be printed in a single pass, announced ETH Zurich. Until now, laborious assembly processes were required to produce complex systems. With the new technology, the systems are printed completely assembled. According to the university, this opens up new possibilities for robotics. As proof, the researchers have printed several robots, including a robotic hand. It was printed layer by layer from plastics with varying degrees of elasticity.

Slow-curing polymers

The new approach uses slow-curing polymers for 3D printing. These have very good elastic properties and return to their original state much more quickly after bending than previously used polyacrylates. Their stiffness can also be very finely adjusted.

"We would not have been able to produce this hand with the fast-curing polyacrylates that we used to use in 3D printing," says Thomas Buchner, lead author of the study.

Printing process was adapted

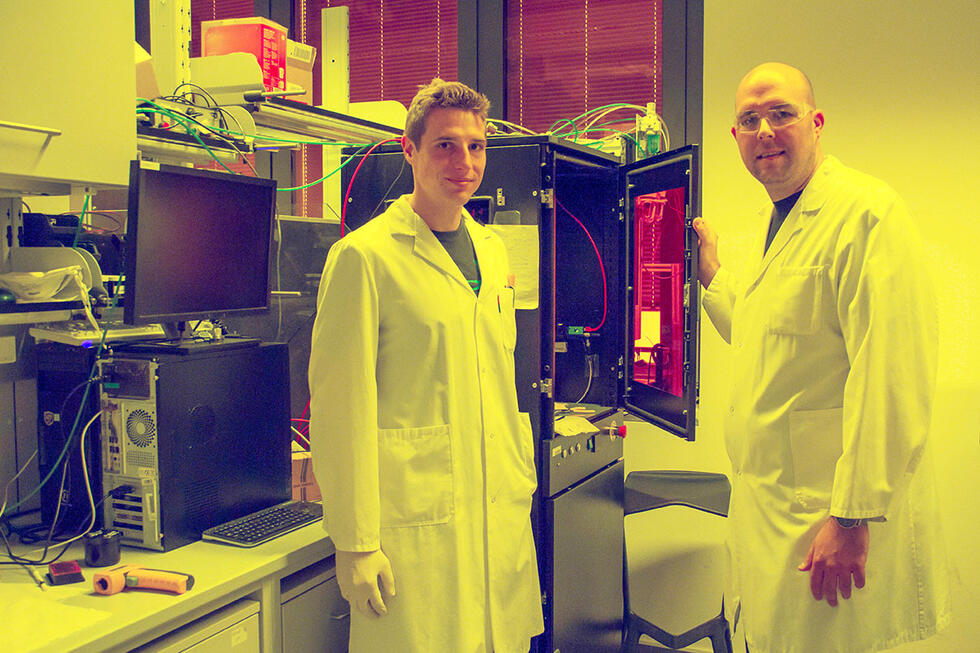

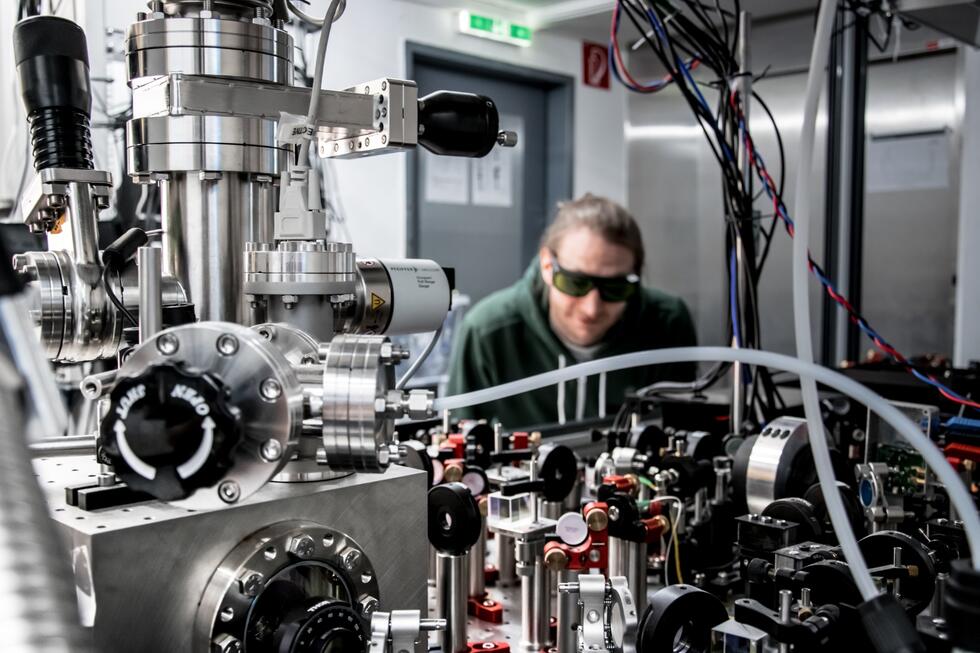

In order to enable 3D printing with slow-curing polymers, the researchers had to make adjustments. Conventional 3D printers apply material layer by layer and cure it immediately. This creates unevenness. These are scraped off with special devices after each curing step.

However, slow-curing polymers would cause these scraping devices to stick together. The researchers therefore developed a 3D laser scanner that recognises the profile of the printed layers. A feedback mechanism compensates for this when printing the next layer by calculating the necessary adjustments to the amount of material to be printed.