New propulsion systems on the test bench

Fossil fuels are a thing of the past, the future of mobility is sustainable. Which propulsion systems live up to this claim and also have what it takes to win through on the mass market? An overview.

Fossil fuels are a thing of the past, the future of mobility is sustainable. Which propulsion systems live up to this claim and also have what it takes to win through on the mass market? An overview.

Diesel engines? Emit too much nitrogen dioxide. Petrol engines? Blast the greenhouse gas carbon dioxide into the atmosphere. Combustion engines, as they are used on our roads today, harm both our environment and our health. In mid-October, the European Environment Agency (EEA) published its “Air Quality Report 2019” on this issue. The report reveals that almost all the inhabitants of European cities are exposed to excessively high levels of pollution. The EEA estimates the total number of premature deaths attributable to particulate matter, nitrogen dioxide, and ozone at approximately 400,000. In addition, many ecosystems, in particular the vegetation, are polluted. One of the culprits: the road transport sector. This is why the vision of a “transport transition” towards more sustainable mobility has been on the agenda for years.

Competition of propulsion technologies

However, the shift in thinking on the roads necessitates a cultural transformation: a reduction of motorized private transport, an increase in car sharing and in the use of bicycles, more efficient public transport. However, since there are inherent limitations to many mobility concepts, and the great potential of car sharing schemes lies primarily in urban areas and less in rural regions, the success of the transport transition also depends on innovative technologies. But which propulsion technologies can contribute towards a large-scale reduction of emissions in the transport sector? Or to put this question in concrete terms: What will be under the hoods of our cars in the future?

Currently, three main ideas are in competition with each other: electric engines, fuel cells, and synthetic fuels.

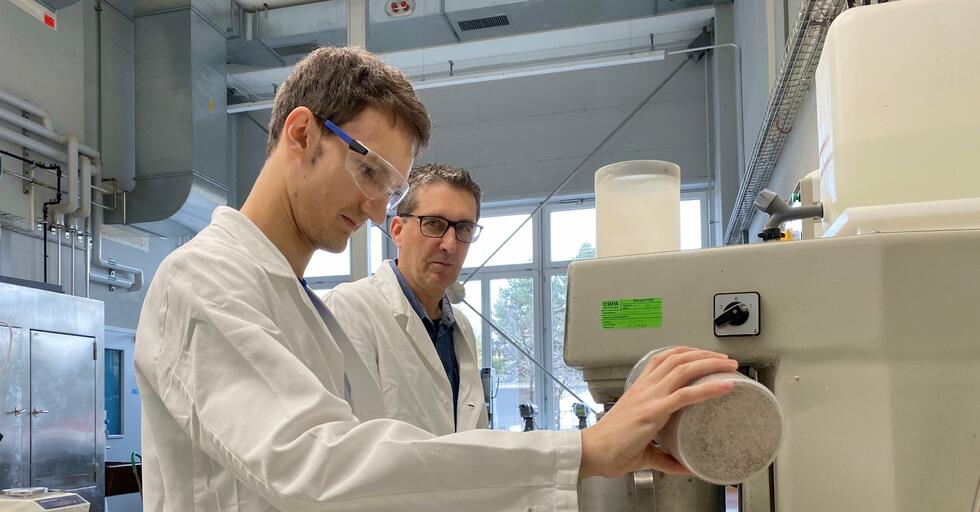

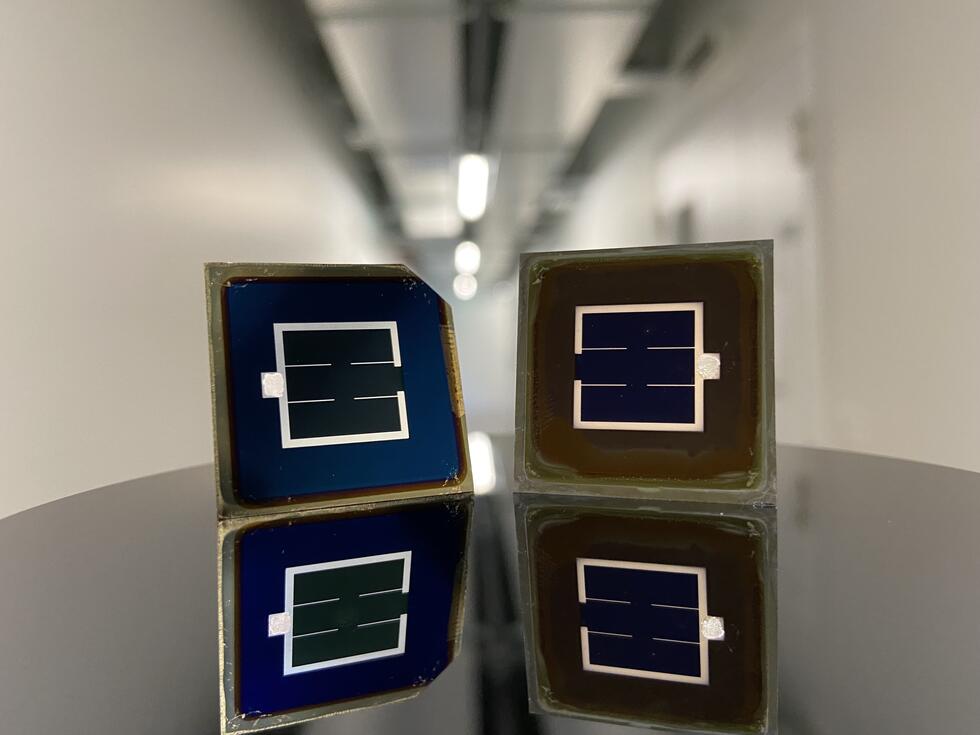

Electric engines driven by compact lithium-ion batteries are already widely available on the market. Hydrogen-powered fuel cell cars are not quite at this stage yet. At present, hydrogen is mainly produced from natural gas, but in the future it will increasingly be generated by using electricity to decompose water in electrolyzers. Stored in pressurized tanks, the hydrogen subsequently reacts with oxygen in a controlled process within the fuel cell and releases the stored electrical energy. Finally, the hopes of many researchers are vested in synthetic fuels – a gasoline or diesel substitute consisting of hydrogen and biogenic residues or carbon dioxide. What all these technologies have in common is that their primary energy is generated using electricity. If this electricity is produced using sustainable resources, the propulsion technologies are potentially carbon neutral.

Efficiency wins

This commonality is contrasted by substantial differences. “In my opinion, the most significant difference is the energy efficiency of the propulsion technologies,” Maximilian Fichtner says. He is the Director of the Helmholtz Institute for Electrochemical Energy Storage in the southern German city of Ulm, one of Europe’s leading centers in this field.

The decisive factor for the mobility of the future is how much energy will be available to us. As long as we do not have the luxury of a surplus of solar and wind energy, we must use the available electricity as efficiently as possible.

A method for calculating the efficiency of propulsion systems is the “well-to-wheel” analysis. It shows how much of the initial energy is converted into motion. Two years ago, the auditing firm PricewaterhouseCoopers (PwC) examined this for all three propulsion technologies. The result: Electric vehicles win the comparison: After electricity generation and storage, 70 percent of the energy is converted into power to the wheels. In the case of fuel cell vehicles, this figure is 36 percent and with vehicles powered by synthetic fuels, eleven percent.

Maximilian Fichtner, who has been researching hydrogen energy storage for the past decade, does not entirely agree with the results. He points out that the study only considers the “stationary utilization” of hydrogen. Thus, it does not take into account the transport to the fueling stations, for which the gas has to be compressed to several 100 bar and cooled to minus 40 degrees. “All in all, hydrogen thus only achieves a 15 percent energy transfer to the wheel, not 36 percent,” he explains.

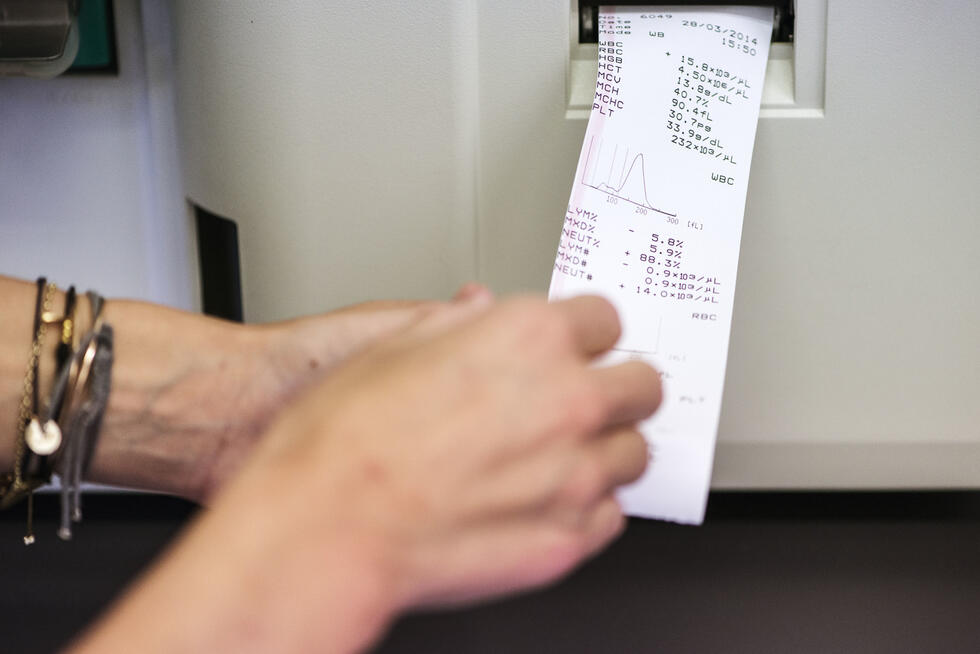

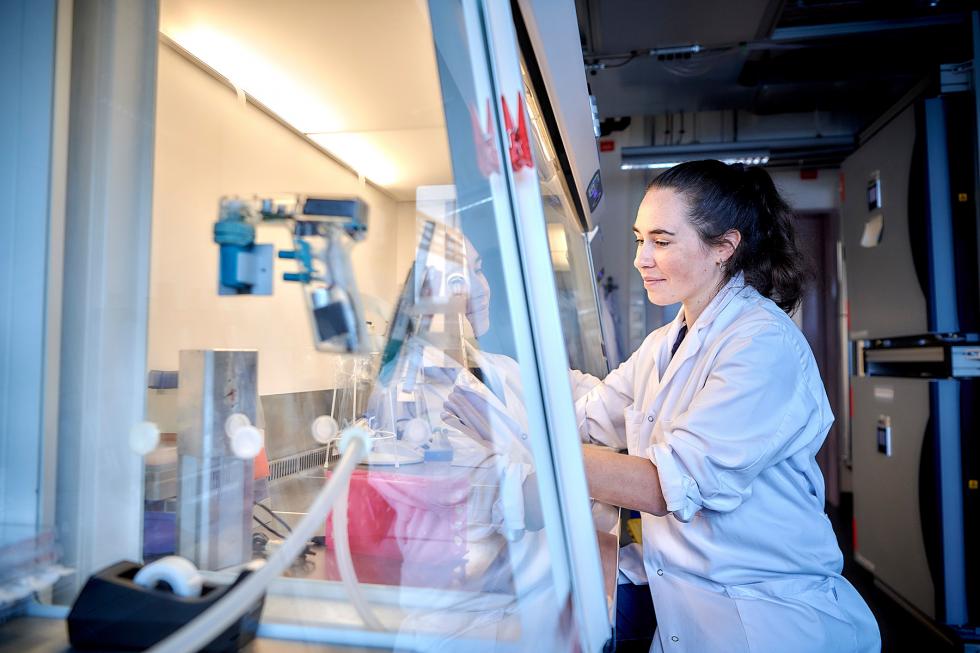

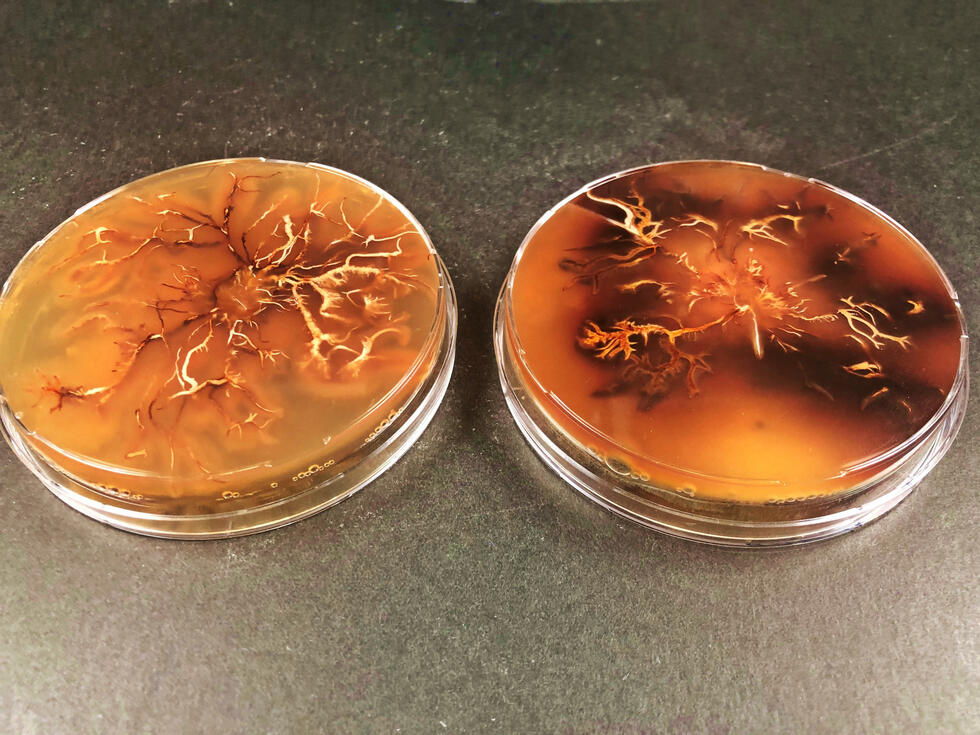

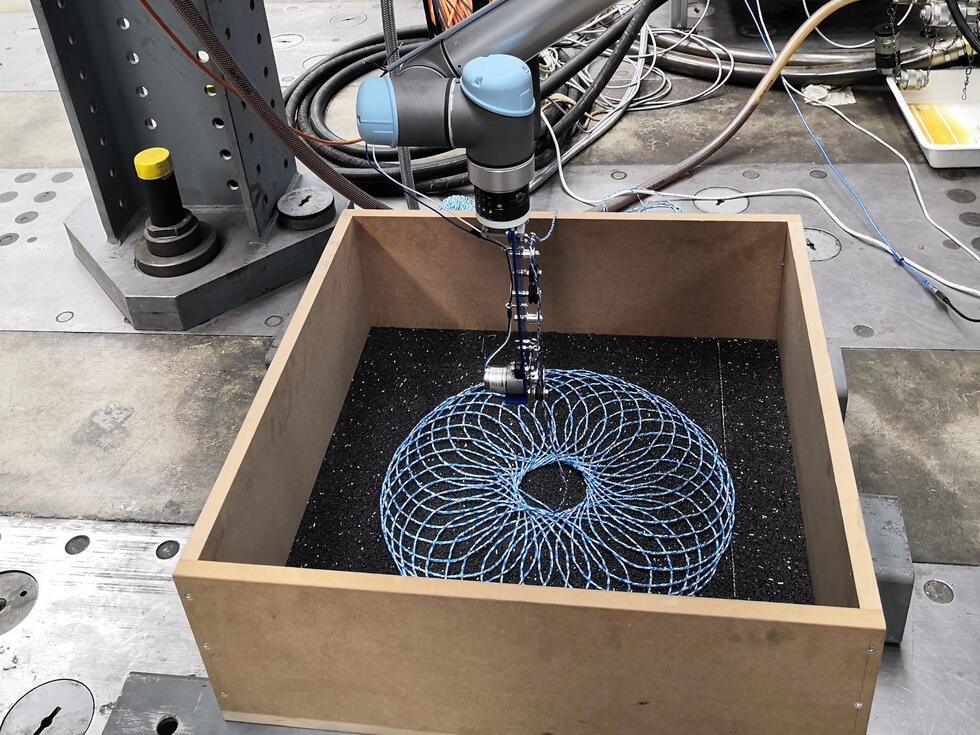

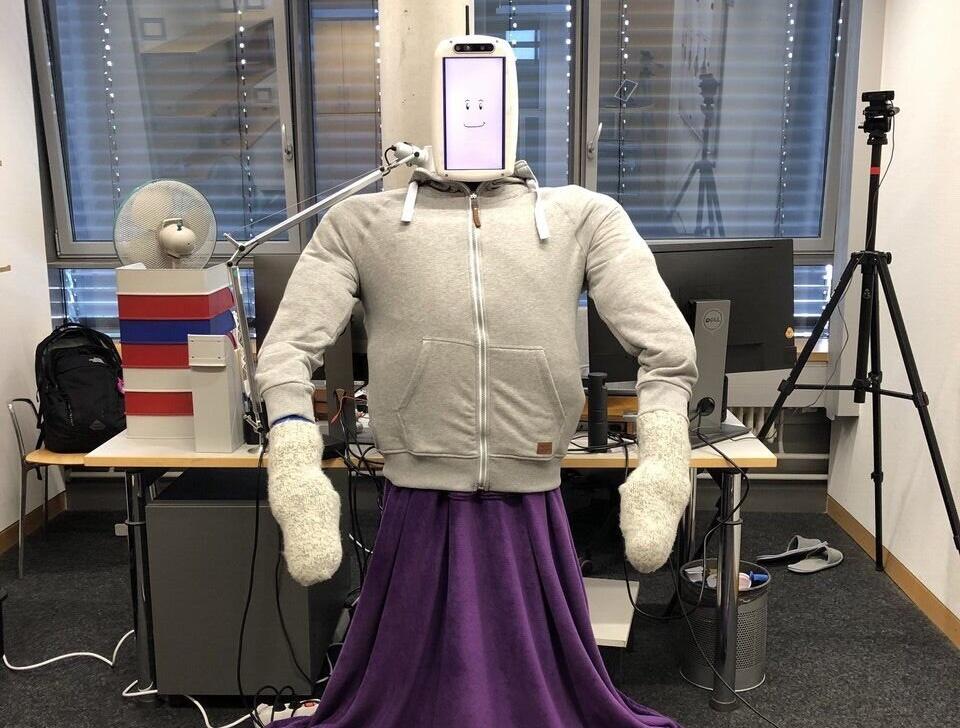

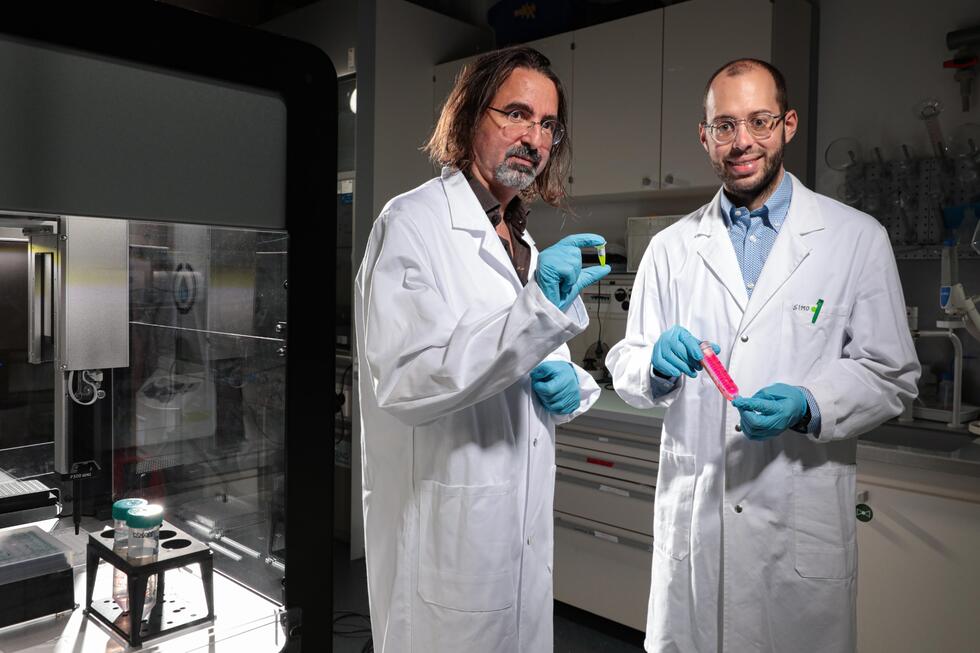

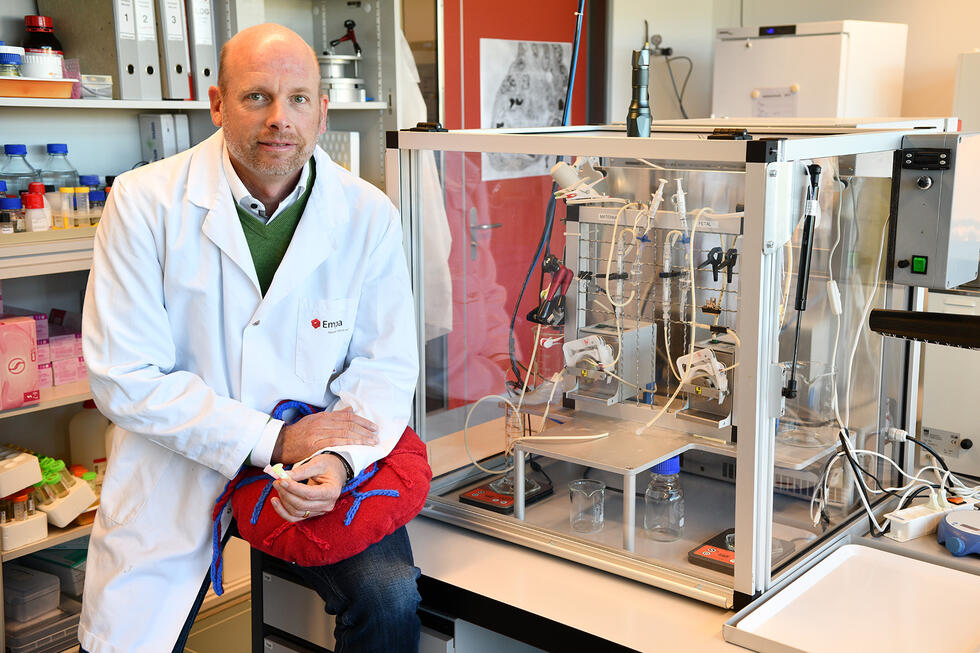

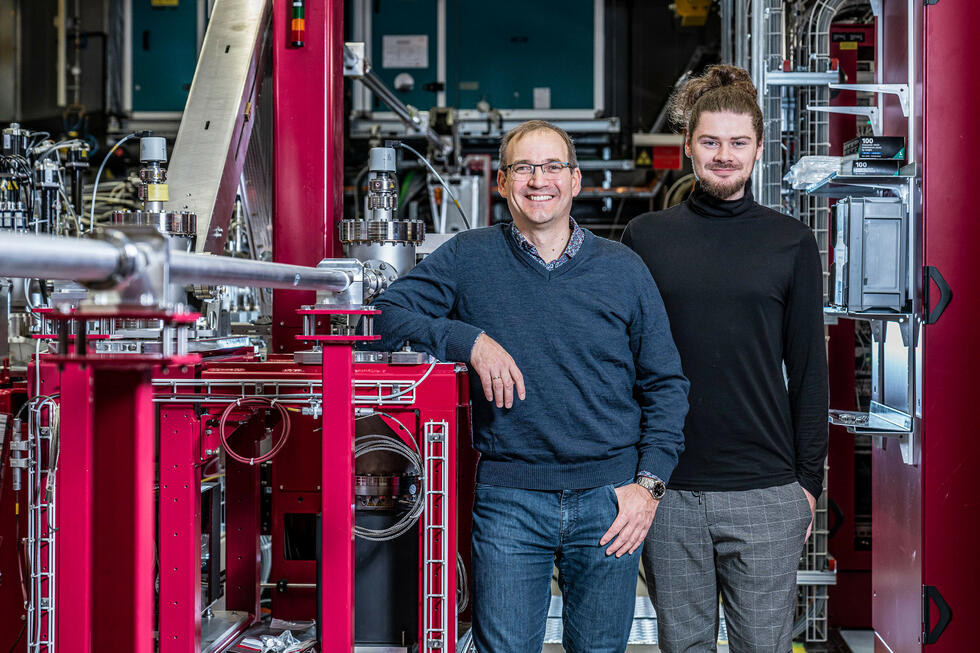

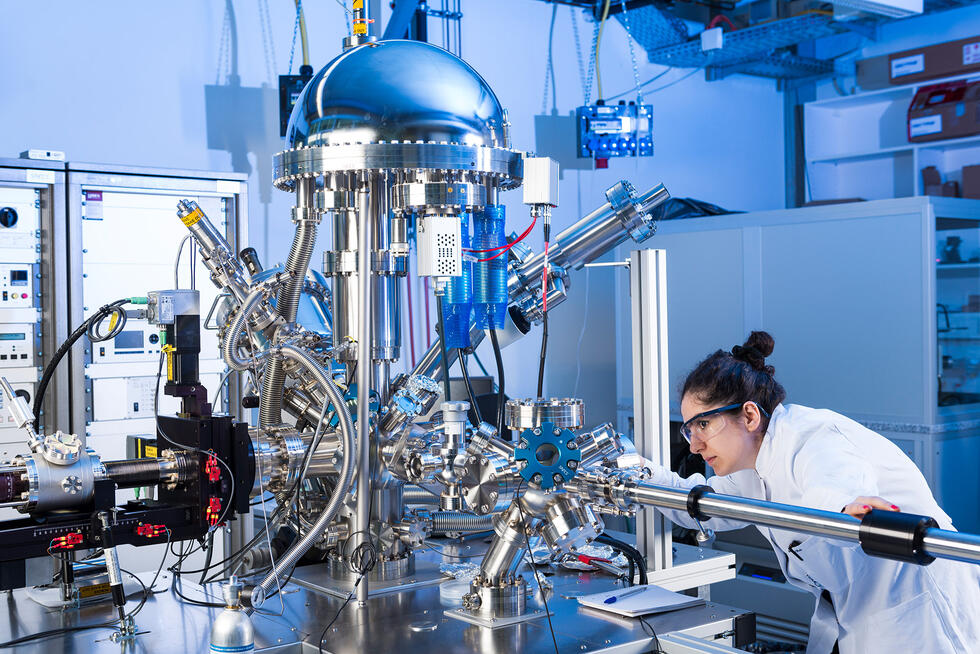

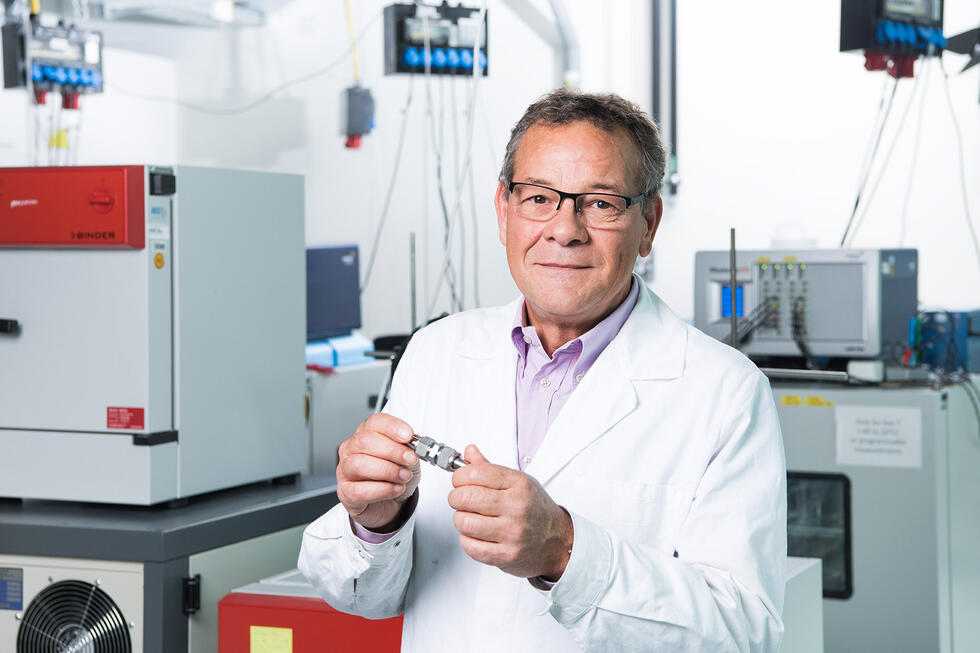

Gallery of employees at the laboratory

The decisive factor is the source of the electricity

Based on their results, the PwC analysts investigated another hypothetical scenario: For Germany, they calculated how much additional electricity would be required if the country’s entire registered car fleet were to run using the alternative propulsion technologies – assuming the same mileage: 176 terawatt hours of additional electricity would be required if everyone drove battery-powered electric cars. 825 terawatt hours would be required additionally if all vehicles were powered by hydrogen, based on the figures of Maximilian Fichtner. 1079 terawatt hours would be the approximate increase in Germany’s electrical energy consumption with synthetic fuels. The challenge here: Last year, only 226 terawatt hours of green electricity were generated nationwide.

However, in spite of the technology’s favorable energy efficiency, relying entirely on battery-powered vehicles is not an option either. For large vehicles, the conventional batteries are not suitable because of their inadequate energy density.

They do not output enough power. Even electrifying SUVs, which are currently so popular, is a double-edged sword. On the one hand, the required electricity can be obtained regeneratively; on the other, batteries for this vehicle class have to be very heavy. “Manufacturing batteries requires large quantities of raw materials and a considerable amount of energy, which must also come from renewable sources. Anyone who takes an environmental stance has to agree: This is where the use of batteries already starts to become counterproductive,” Maximilian Fichtner emphasizes. And what is more: According to forecasts, the key raw materials for electric mobility, lithium and cobalt, are at risk of facing supply bottlenecks as demand rises rapidly. In some of South America’s lithium-rich salt lakes, the extraction of large quantities of the saline groundwater, which is subsequently evaporated to recover the lithium, is also leading to a drop in groundwater levels.

Mining of raw materials raises questions

But those who put their hopes in hydrogen also have to face a debate about raw materials. “Fuel cells require platinum as a catalyst,” Maximilian Fichtner explains. “This precious metal is extremely rare and it is often mined under very poor working conditions.” In their study, the German aid organization “Brot für die Welt” reports that in South Africa – the world market leader for platinum mining – the metal is inextricably linked to environmental pollution and human rights violations.

Even with synthetic fuels, there was a heated “fuel or plate debate” a few years ago focusing on the regenerative portion of bio-diesels. So far, most of the fuel has been produced using rapeseed, which raised the question: Should earth’s limited agricultural areas be used exclusively for food production or also to produce synthetic fuels? For modern synthetic fuels, the necessary carbon content should thus stem from biogenic residues such as straw, food leftovers, or waste fats.

Billions required in infrastructure investments

While battery technology is primarily suitable for light-weight cars, the main potential of synthetic fuels and fuel cells lies in heavy vehicles. This is due to their energy density: During the fueling process, energy in the megawatt range flows into the tank every minute. Both technologies are suitable for trucks, buses, and even trains.

In northern Germany, two prototypes of a fuel cell train have been in operation since autumn 2018. The potential on the tracks is vast: Approximately 46 percent of Europe’s rail network are not electrified. Diesel locomotives – the current solution – could in future also be powered using synthetic fuels.

The strongest argument in favor of synthetic fuels, however, can be spotted at regular intervals on the roadside: the global network of gas stations. This infrastructure could continue to serve its purpose. And since only the fuel that is burned changes, this also applies to the interior of the vehicles.

Quite the opposite is true for battery and hydrogen-powered vehicles. According to the German Jülich Research Institute, the expansion of the supply networks for these two technologies would cost around 91 billion euro in Germany alone. This calculation is based on the assumption of 40 million vehicles, divided equally into battery and hydrogen technology. “The costs are so high because a medium-voltage distribution grid would have to be established to provide several thousand volts at the electric charging stations. Otherwise, future owners of electric cars will face half-hour charging breaks,” Maximilian Fichtner says.

Combining is the solution

For consumers, the running costs of each of the three technologies will most likely be one of the decisive factors. Hence, the consulting firm PwC compared the costs for fuel, servicing, and depreciation of similar mid-range vehicles, factoring in economies of scale, technological potential, and expected increases in efficiency. The result: 100 kilometers cost 49.90 euro for a battery-powered electric car, 55.50 euro for a hydrogen-powered car and 69.30 euro for a car running on synthetic fuels.

So which propulsion technology will prevail? Maximilian Fichtner’s answer is surprising:

“None. We need a combination of all technologies. While batteries simply cannot cover every form of mobility, it equally make no sense to increase the energy required to power small vehicles several times over by relying exclusively on fuel cells or synthetic fuels. Moreover, synthetic fuels are still just a promise: In spite of the incredible advantage of being able to retain the existing vehicle fleet and the refueling infrastructure, synthetic fuels require too much energy to produce and are currently still too expensive. The fuel cell is also trailing behind, which is why it is roughly twice as expensive as a battery. Lithium-ion batteries are by far the most energy-efficient solutions and they also have a very long service life. Their high use of raw materials can be mitigated if we establish a recycling economy for batteries, as the industry and policy-makers are currently aiming to achieve.”

Written by:

Photos: Laila Tkotz, Amadeus Bramsiepe, Elvira Eberhardt