SHORT NEWS

Green electricity takes liquid form: pilot plant for e-fuel up and running

Wind and solar electricity can now be turned into climate-neutral fuels: E-fuels have the potential to play an important role in combating climate change. Scientists in Karlsruhe, Germany, are laying a technological foundation.

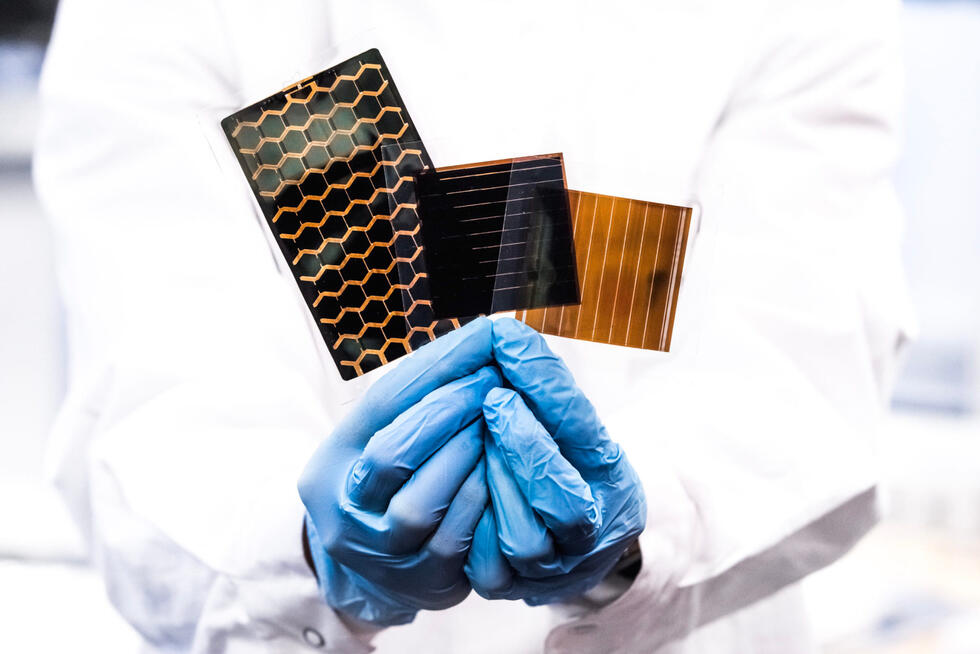

The climate-neutral fuel still flows only in droplets from the test facility near Karlsruhe. In the future, however, the synthetic fuel, also known as e-fuel – which is to be mass-produced using air and green electricity – will be used to power trucks, ships, and aircraft.

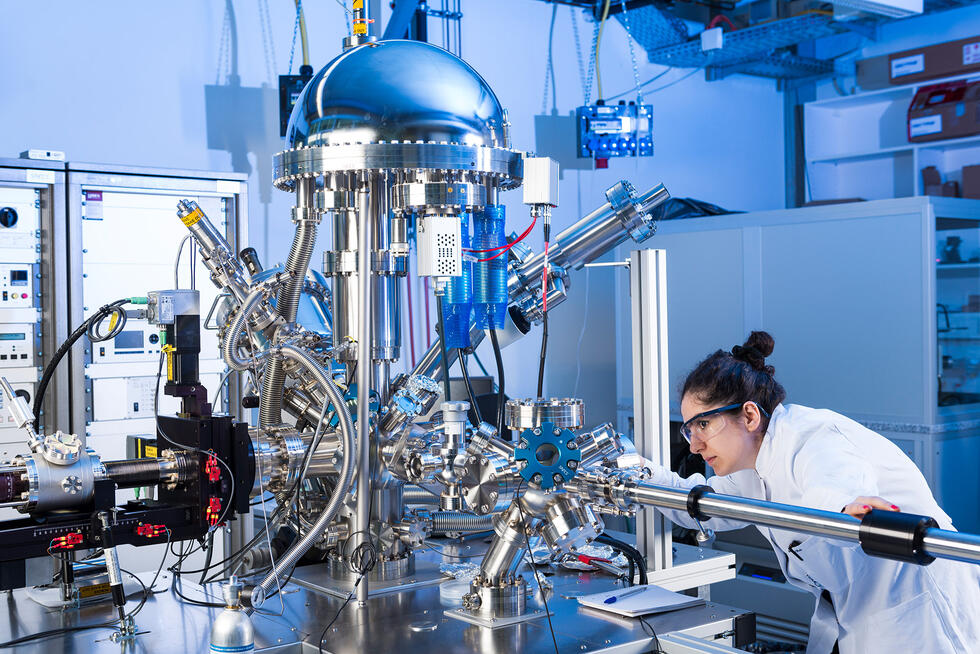

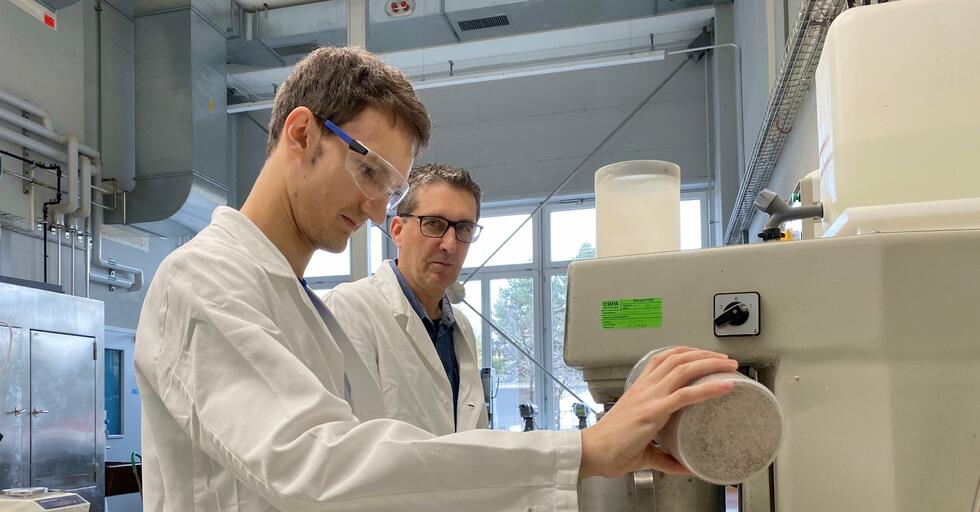

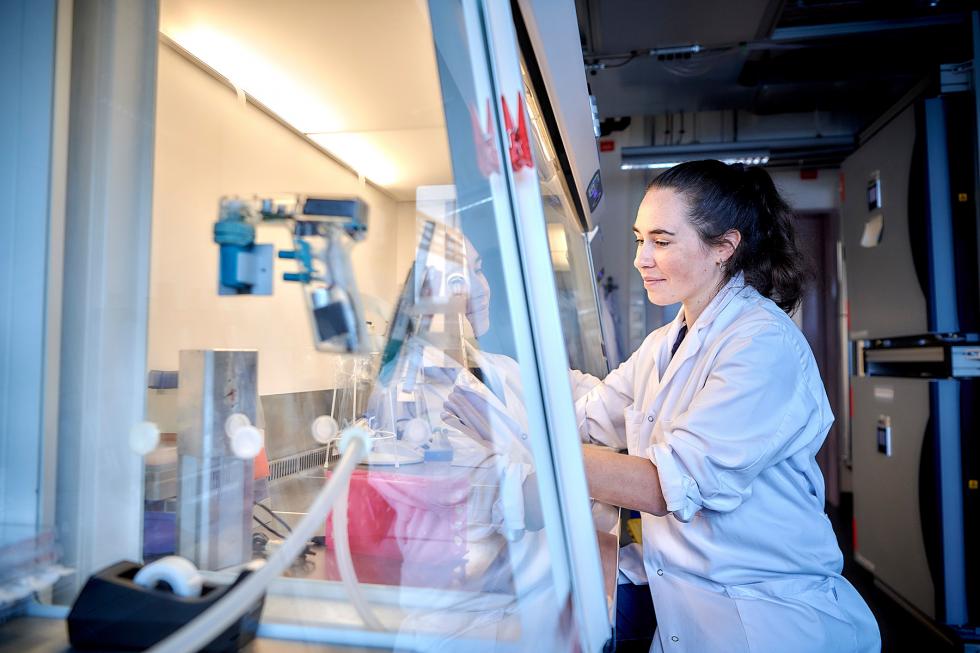

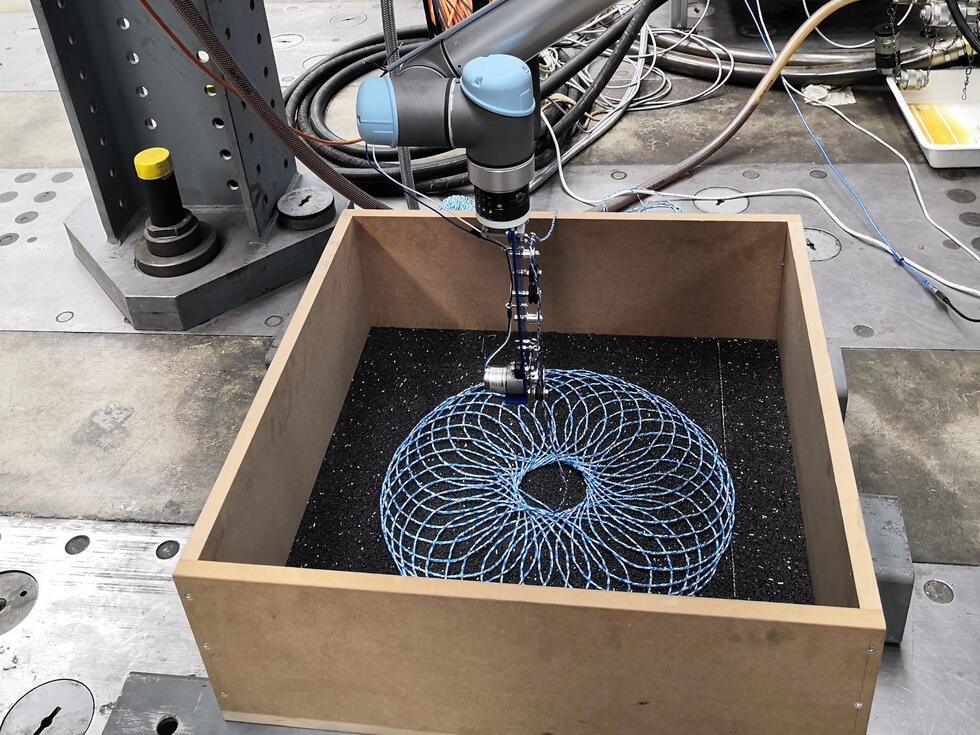

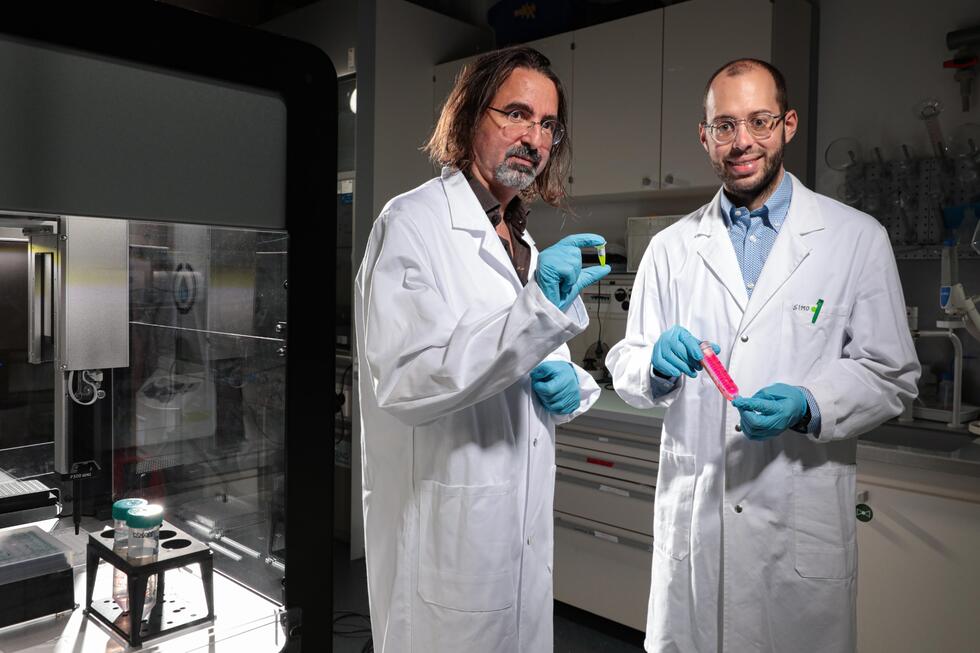

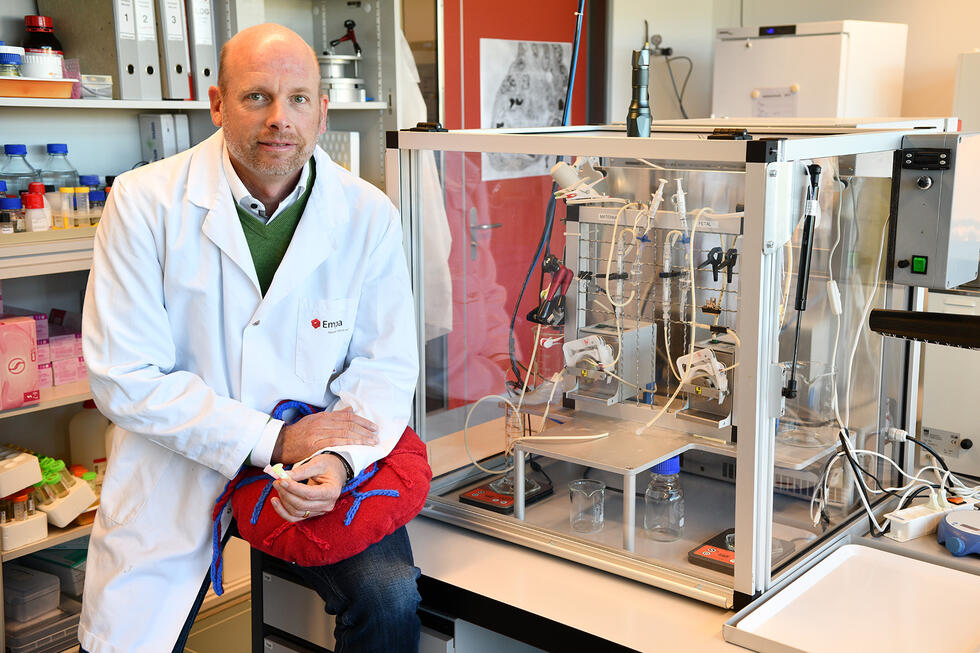

For the first time ever, a compact plant for the production of e-fuel, which combines all the various production steps, was recently put into operation at the Karlsruhe Institute of Technology (KIT).

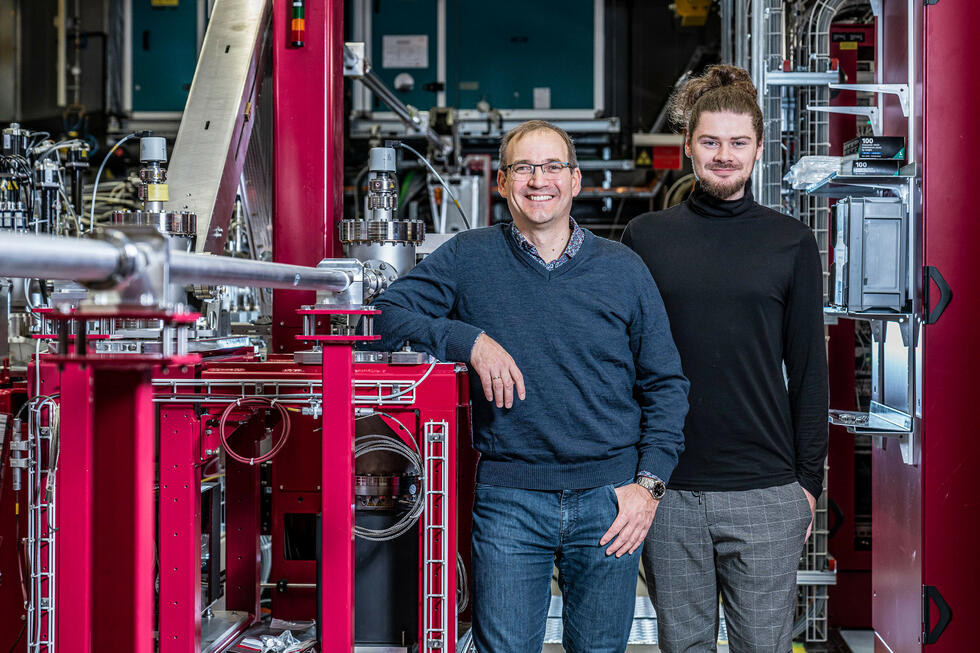

During the official launch of the plant, which is the size of a shipping container, KIT Professor Thomas Hirth spoke about the refinement of renewable energies. The plant on the KIT campus in Eggenstein-Leopoldshafen on the outskirts of Karlsruhe is the first of its kind worldwide, emphasized the project partners who are collaborating under the umbrella of the Copernicus Projects funded by the German government to the tune of millions of euro.

Four steps

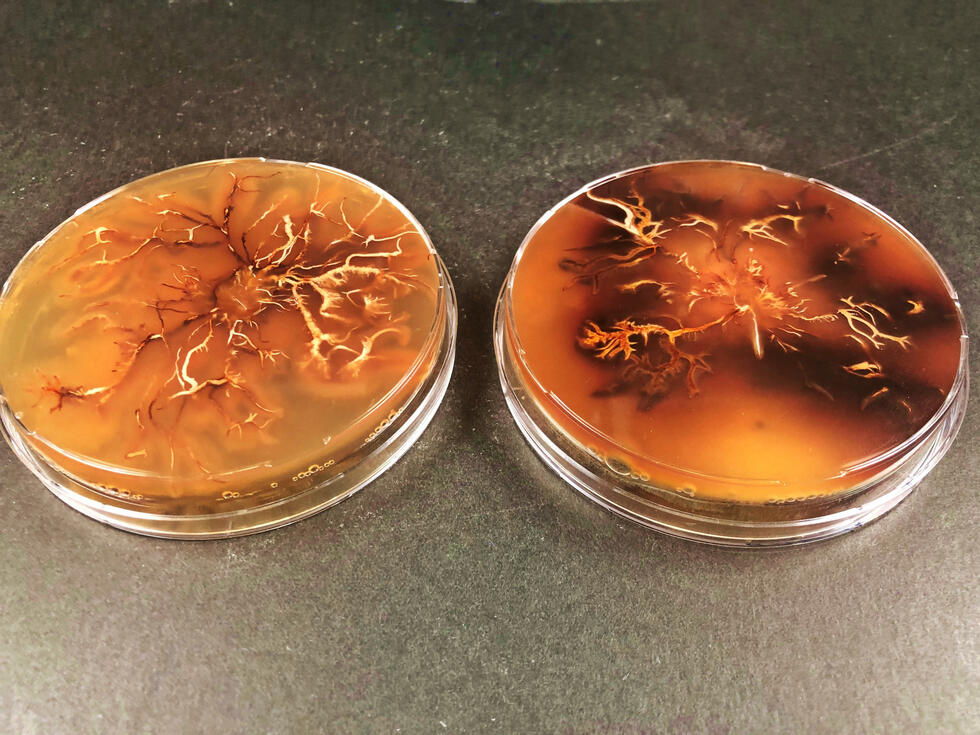

The CO2-neutral fuel is produced using green electricity in four steps: First, the plant filters carbon dioxide (CO2) from the air. Then CO2 and water vapor are split into hydrogen and carbon monoxide. In the third phase, these are transformed into long hydrocarbon chains. In the fourth and final step, these chains are split in such a way as to produce petrol, diesel, or kerosene.

Although during the initial trials, the small test facility has already filled a barrel with e-fuel, it only produces a few liters a day. According to Professor Roland Dittmeyer, one of the initiators of the project at KIT, this is about to change. The next phase of the project is expected to achieve a daily output of 200 liters. The researchers aim to reach industrial maturity within ten years.

CO2 from the air

One major benefit of the technology is that it captures CO2 from the air. “This has the advantage that the plants can be set up anywhere around the globe,” Roland Dittmeyer emphasized. In this way, fuel could also be produced using solar systems that are not connected to the conventional energy supply grid. In Germany, the plant could be powered using surplus green electricity. During periods of strong wind and sunshine, wind turbines and photovoltaic systems often generate far more electricity than is actually consumed.

The project partners do not yet want to speculate about the expected costs per liter of e-fuel, because the technology is still in its infancy. The most important factor is the electricity price.

Peter Müller-Baum from the German Engineering Federation referred to this as an industrial policy opportunity. It is important, he said, to be the world market leader not just in terms of the technology itself. Such plants must also be built and operated in Germany. In order to help e-fuels achieve a breakthrough, a significantly higher CO2 price than the ten euro per metric tonne envisaged by the German government would be required.